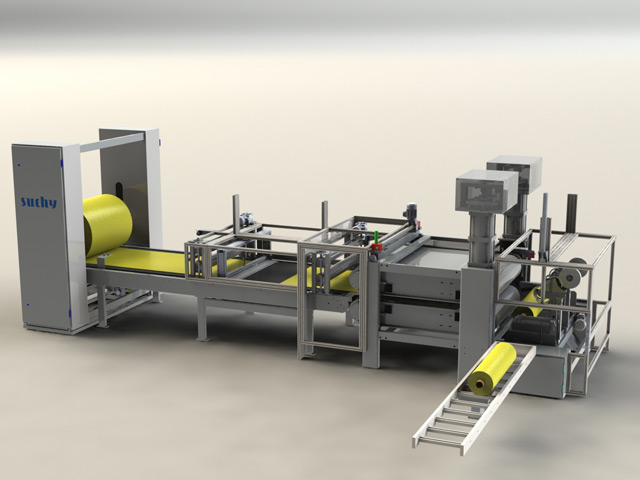

Where, in the past, several assemblies and machines were needed, this system allows everything to be done in one compact unit with chronologically matched sequences. This ensures optimum process flow, saves intermediate steps, production area and working time.

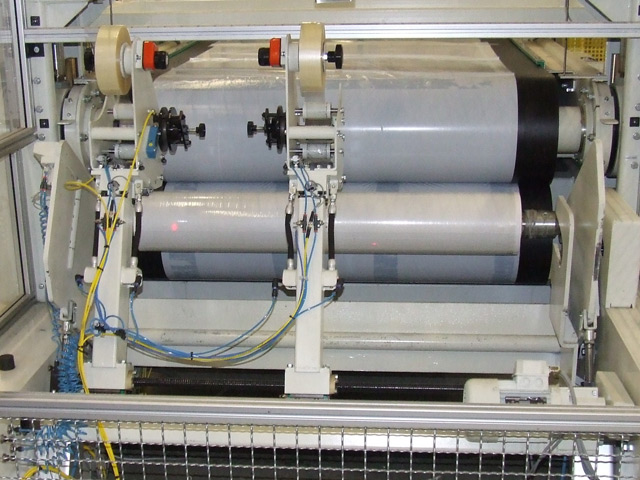

Mainly consisting of removal and start-up sections, automatic cross cutting unit, compression section and the winding section with banding, our system is in use at our customer who mainly specialises in seals and sound insulation also for international markets. Its functional interactions extend up to finished, ready-to-ship fabric rolls.