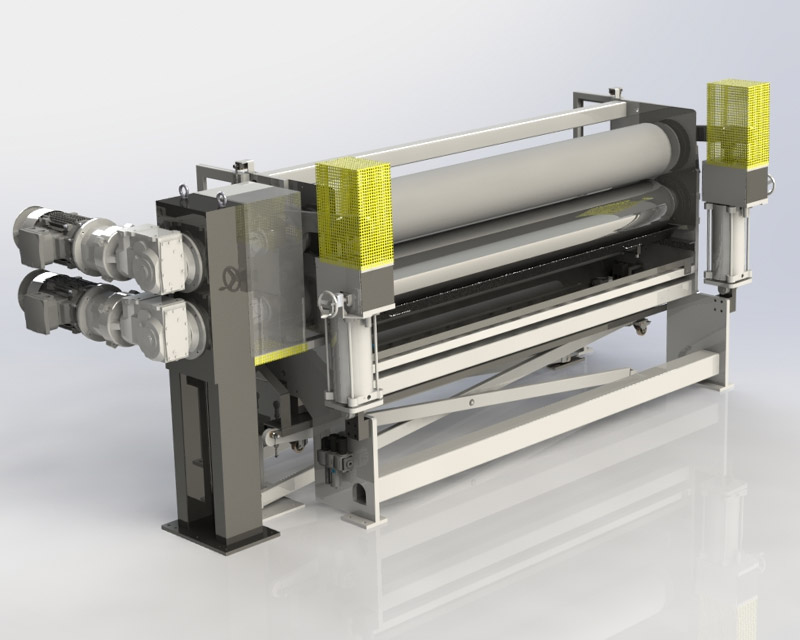

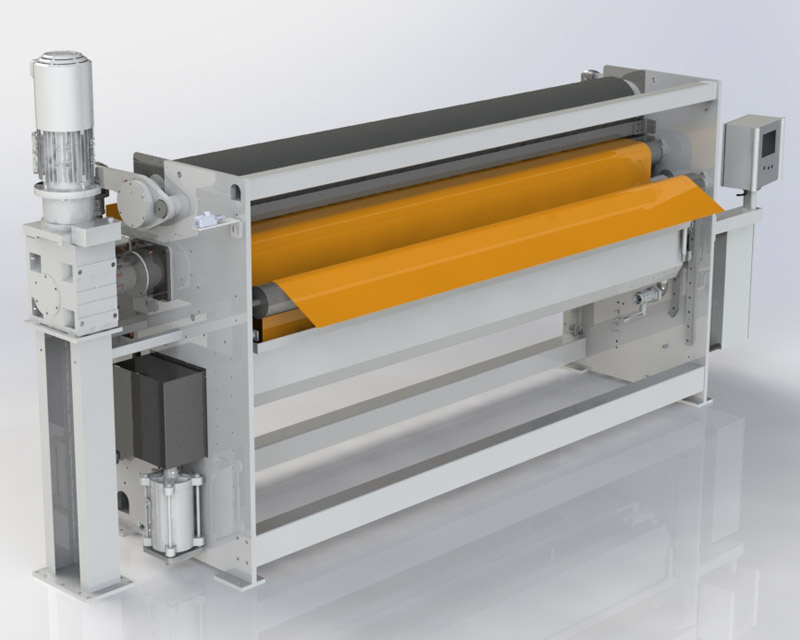

- Padder

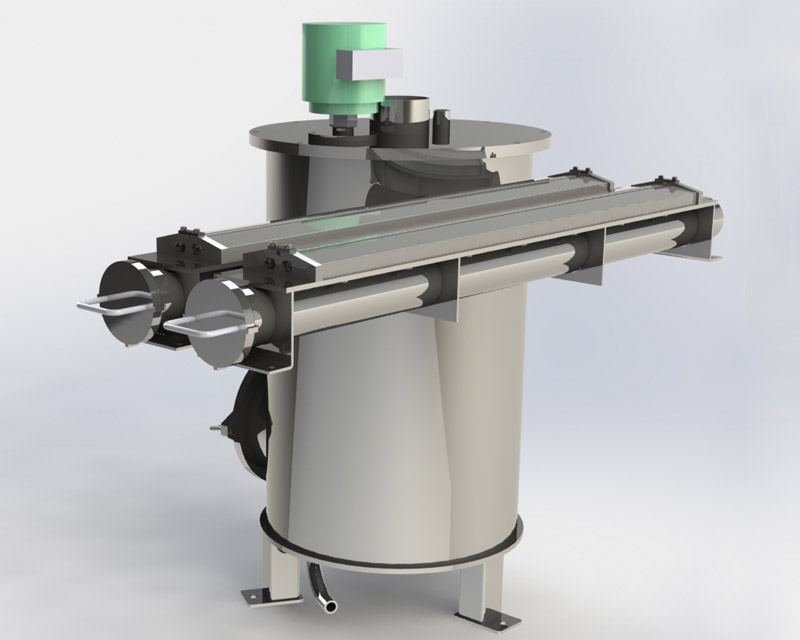

- Vaccum beam

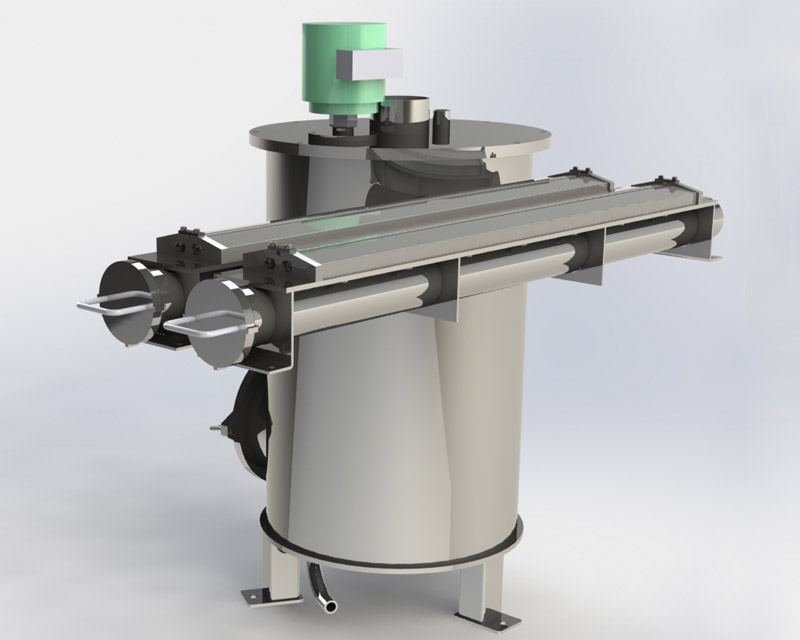

- Annular suction nozzle

With the respectively customised roll system, the padder can be used for difficult materials, media and technologies. Independent of line loads and working widths (to 6,000 mm), its high load capacity with uniform roll contact pressure is appropriate for both vertical and horizontal roll arrangements, thus providing … read more the necessary safety in the application process. For special applications, variable bending line control during the production process is possible. The matching padder trough version can always be selected from a wide range in accordance with the application criteria. In the event of expansion, the padder with integrated kiss roll unit offers a practical solution. We regard greatest possible permanent availability, excellent results and a high degree of operating and maintenance convenience, fastest possible service for roll regeneration as a continuous commitment to our customers.

Padder

- Roll widths up to 6,000 mm

- Line loads up to 750 N/mm

- Active sag compensation

- Different roll covers

- Horizontal and vertical roll arrangement

- Different trough versions

Highly effective yet gentle dehumidification or penetration of textiles, especially those made of synthetic fibres as well as textile-like, permeable fabrics, is an important attribute of the vacuum dehumidification system. A special slotted nozzle with associated vacuum slot geometry is fastened to the low-maintenance … read more vacuum pipe assembly and, adjusted to the fabric width, can also be used effectively. The full dehumidification performance and evenness can be achieved in interaction with optimally designed assemblies, consisting of separator, rotary blowers, sound suppressors, pump and switching system even for larger fabric widths. Connecting together several slotted nozzles installed in parallel in a stationary or even moving configuration is also possible.

Vaccum beam

- Roll widths 200–6,000 mm

- Vacuum to 500 mbar

- Different gap geometry

- Automatic gap covering

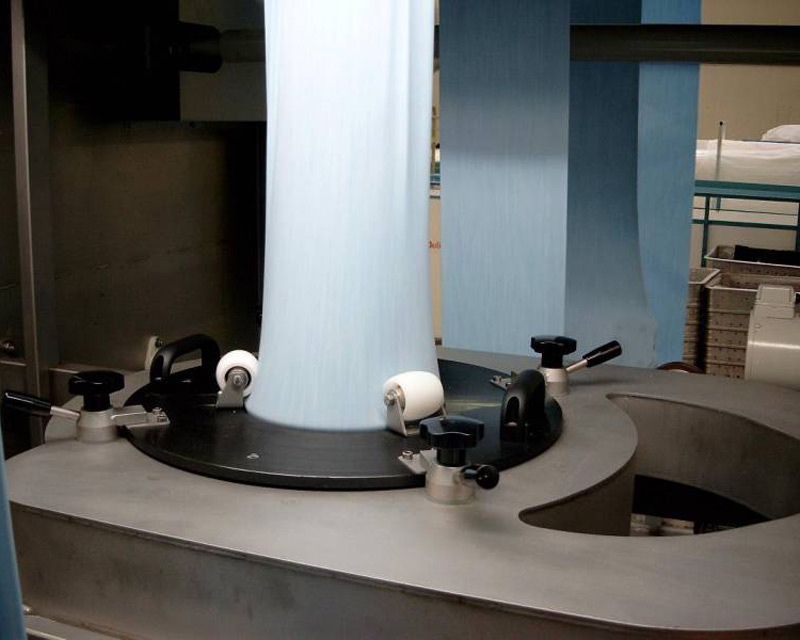

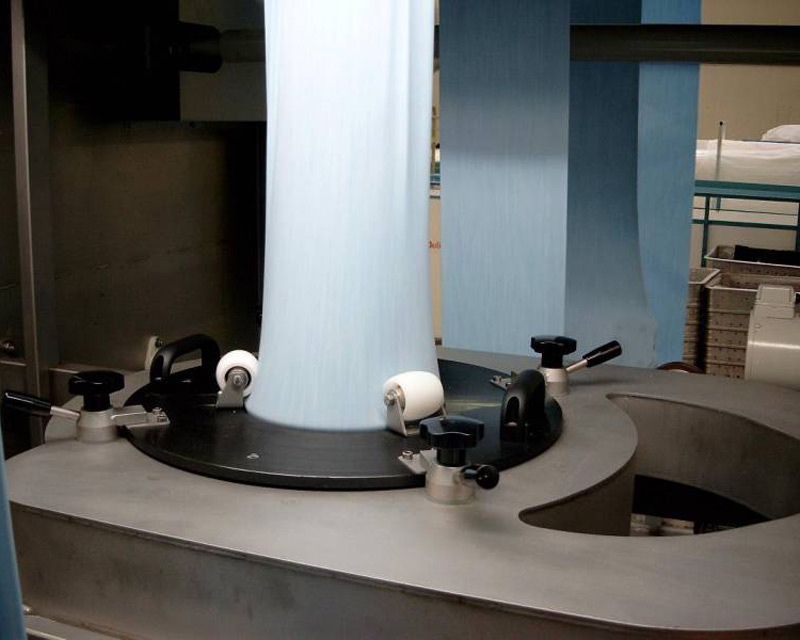

The vacuum dehumidification of tubular fabric constitutes a unique, patented process that meets the highest quality demands with its technical maturity and effectiveness. The central element of the system is the annular suction nozzle assembly. This guarantees fabric that is free of creases and bow edges and that is stretched … read more in width and machine-straightened at the same time during the nozzle passage. Especially low tension feeding of the fabric applies throughout the entire fabric run and maintains the elasticity of the tubular fabric. Low, uniform residual humidity ensures that subsequent thermal processes can be carried out in an effective and energy-saving manner.

Annular suction nozzle

- Tubular widths from 30–120 cm

- Vacuum to 500 mbar

- Dewatering and finishing possible

- Shrinkage and overstretching unit

- Optional hose cutting